Wire

Ropes

Wire

Rope Construction

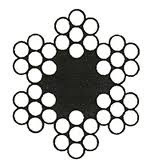

Essentially,

it is made of a number of strands laid helically about a metallic or

non-metallic core. Each strand composed of a number of wires also

laid helically . Various types of wire rope have been

developed to meet a wide range of uses and operating conditions.

These types classified by the kind of core; number of strands; the

number, sizes and wire arrangement in each strand.

Wire

Rope Materials

Materials

used in the manufacture of wire ropes are, in the order of

increasing strength: iron, phosphor bronze, traction steel, plow

steel, improved plow steel and bridge rope steel. Iron wire

rope is largely used low strength applications such as elevator

ropes not used for hoisting and for stationary guy ropes.

Phosphor

bronze wire rope is used occasionally for elevator

governor-cable rope and marine applications as life lines, clearing

lines, wheel ropes and rigging.

Traction

steel wire rope is primarily used as hoist rope for

passenger and freight elevators of the traction drive type, an

application for which it was specifically designed.

Galvanized

wire or coated with zinc by the electrode position process are

used in certain applications where additional protection against

rusting is required.

Galvanized

carbon steel, tinned carbon steel and stainless steel are used

for small cords and strands ranging in diameter from 1/64” to 3/8”

and larger.

Properties

of Wire Rope

Important

properties of wire ropes are strength, wear resistance, flexibility

and resistance to crushing and distortion.

Strength:

The strength of a wire rope depends upon its size, material,

number, type of core and whether the the wire is galvanized or not.

Strengths of various types and sizes of wire ropes are

given in the accompanying tables together with appropriate factors to

apply for ropes with steel cores and galvanized wire ropes.

Wear

Resistance: Wire rope which in use must pass back

and forth over surfaces which subject is too unusual wear or abrasion

must be specially constructed for reliable service.

Flexibility:

Wire rope which undergoes repeated and severe bending, such as

in passing around small sheaves, must have a high degree of

flexibility to prevent premature breakage due to over fatigue.

Resistance

to Crushing and Distortion: Where wire rope is to

be subjected to transverse loads that may crush or distort it, care

should be taken to select a type of construction which can withstand

that operating conditions.

Standard

Classes of Wire Rope

Wire

rope is commonly designated by two figures, the first indicating

the number of strands and the second, the number of wires per strand.

6

x 7 Class ( Standard Course Laid Rope ): Wire

ropes in this class are for use where resistance to wear, as in

dragging over the ground or across rollers, is an important

requirement. Heavy hauling rope transmissions, wheel drilling are

common applications.

Diameter, inches

|

Weight per Foot,

lbs.

|

Breaking

Strength, Tons of 2000 Pounds

|

||

Improved Plow

Steel

|

Plow Steel

|

Mild Plow Steel

|

||

1/4

|

0.094

|

2.64

|

2.30

|

2.00

|

5/16

|

0.15

|

4.10

|

3.56

|

3.10

|

3/8

|

0.21

|

5.86

|

5.10

|

4.43

|

7/16

|

0.29

|

7.93

|

6.90

|

6.00

|

1/2

|

0.38

|

10.3

|

8.96

|

7.79

|

9/16

|

0.48

|

13.0

|

11.3

|

9.82

|

5/8

|

0.59

|

15.9

|

13.9

|

12.0

|

3/4

|

0.84

|

22.7

|

19.8

|

17.2

|

7/8

|

1.15

|

30.7

|

26.7

|

23.2

|

1

|

1.50

|

39.7

|

34.5

|

30.0

|

1 1/8

|

1.90

|

49.8

|

43.3

|

37.7

|

1 1/4

|

2.34

|

61.0

|

53.0

|

46.1

|

1 3/8

|

2.84

|

73.1

|

63.6

|

55.3

|

1 1/2

|

3.38

|

86.2

|

75.0

|

65.2

|

6

x 19 Class ( Standard Hoisting Rope ): This is the most

popular and widely used class. This class are furnished in regular

or lay and may be obtained preformed or not preformed. Cores may be

of fiber, independent wire rope or wire strand.

Diameter, inches

|

Weight per Foot,

lbs.

|

Breaking

Strength, Tons of 2000 Pounds

|

||

Improved Plow

Steel

|

Plow Steel

|

Mild Plow Steel

|

||

1/4

|

0.10

|

2.74

|

2.39

|

2.07

|

5/16

|

0.16

|

4.26

|

3.71

|

3.22

|

3/8

|

0.23

|

6.10

|

5.31

|

4.62

|

7/16

|

0.31

|

8.27

|

7.19

|

6.25

|

1/2

|

0.40

|

10.7

|

9.35

|

8.13

|

9/16

|

0.51

|

13.5

|

11.8

|

10.2

|

5/8

|

0.63

|

16.7

|

14.5

|

12.6

|

3/4

|

0.90

|

23.8

|

20.7

|

18.0

|

7/8

|

1.23

|

32.2

|

28.0

|

24.3

|

1

|

1.60

|

41.8

|

36.4

|

31.6

|

1 1/8

|

2.03

|

52.6

|

45.7

|

39.8

|

1 1/4

|

2.50

|

64.6

|

56.2

|

48.8

|

1 3/8

|

3.03

|

77.7

|

67.5

|

58.8

|

1 1/2

|

3.60

|

92.0

|

80.0

|

69.6

|

1 5/8

|

4.23

|

107

|

93.4

|

81.2

|

1 3/4

|

4.90

|

124

|

108

|

93.6

|

1 7/8

|

5.63

|

141

|

123

|

107

|

2

|

6.40

|

160

|

139

|

121

|

2 1/8

|

7.23

|

179

|

156

|

….

|

2 1/4

|

8.10

|

200

|

174

|

….

|

2 1/2

|

10.0

|

244

|

212

|

….

|

2 3/4

|

12.1

|

292

|

254

|

….

|

6

x 37 Class ( Extra Flexible Hoisting Rope ): For given

size of rope, the component wires are of smaller diameter than those

in the two classes previously described and hence have less

resistance to abrasion.

Diameter,

( inches )

|

Weight per Foot,

( lbs. )

|

Breaking

Strength, Tons of 2000 Pounds

|

|

Improved Plow

Steel

|

Plow Steel

|

||

1/4

|

0.10

|

2.59

|

2.25

|

5/16

|

0.16

|

4.03

|

3.50

|

3/8

|

0.22

|

5.77

|

5.02

|

7/16

|

0.30

|

7.82

|

6.80

|

1/2

|

0.39

|

10.2

|

8.85

|

9/16

|

0.49

|

12.9

|

11.2

|

5/8

|

0.61

|

15.8

|

13.7

|

3/4

|

0.87

|

22.6

|

19.6

|

7/8

|

1.19

|

30.6

|

26.6

|

1

|

1.55

|

39.8

|

34.6

|

1 1/8

|

1.96

|

50.1

|

43.5

|

1 1/4

|

2.42

|

61.5

|

53.5

|

1 3/8

|

2.93

|

74.1

|

64.5

|

1 1/2

|

3.49

|

87.9

|

76.4

|

1 5/8

|

4.09

|

103

|

89.3

|

1 3/4

|

4.75

|

119

|

103

|

1 7/8

|

5.45

|

136

|

118

|

2

|

6.20

|

154

|

134

|

2 1/8

|

7.00

|

173

|

150

|

2 1/4

|

7.85

|

193

|

168

|

2 1/2

|

9.69

|

236

|

205

|

2 3/4

|

11.72

|

284

|

247

|

3

|

14.0

|

335

|

291

|

3 1/4

|

16.4

|

390

|

339

|

3 1/2

|

19.0

|

449

|

390

|

8

x 19 Class ( Special Flexible Hoisting Rope ): This is a

stable smooth running rope, specially suitable, because of its

flexibility, for high speed operation with reverse bends. This class

are available in regular lay with fiber core.

Diameter,

( inches )

|

Weight per Foot,

( lbs. )

|

Breaking

Strength, Tons of 2000 Pounds

|

|

Improved Plow

Steel

|

Plow Steel

|

||

1/4

|

0.09

|

2.35

|

2.04

|

5/16

|

0.14

|

3.65

|

3.18

|

3/8

|

0.20

|

5.24

|

4.55

|

7/16

|

0.28

|

7.09

|

6.17

|

1/2

|

0.36

|

9.23

|

8.02

|

9/16

|

0.46

|

11.6

|

10.1

|

5/8

|

0.57

|

14.3

|

12.4

|

3/4

|

0.82

|

20.5

|

17.8

|

7/8

|

1.11

|

27.7

|

24.1

|

1

|

1.45

|

36.0

|

31.3

|

1 1/8

|

1.84

|

45.3

|

39.4

|

1 1/4

|

2.27

|

55.7

|

48.4

|

1 3/8

|

2.74

|

67.1

|

58.3

|

1 1/2

|

3.26

|

79.4

|

69.1

|

18

x 7 Class ( None Rotating Rope ): This wire rope

specially designed for use where a minimum of rotating or spinning is

called for, especially in the lifting or lowering of free loads with

a single part line. The combination of opposing lays tends to prevent

rotation when the rope is stretched.

Diameter,

( inches )

|

Weight per Foot,

( lbs. )

|

Breaking

Strength, Tons of 2000 Pounds

|

|

Improved Plow

Steel

|

Plow Steel

|

||

3/16

|

0.061

|

1.42

|

1.24

|

1/4

|

0.108

|

2.51

|

2.18

|

5/16

|

0.169

|

3.90

|

3.39

|

3/8

|

0.24

|

5.59

|

4.86

|

7/16

|

0.33

|

7.58

|

6.59

|

1/2

|

0.43

|

9.85

|

8.57

|

9/16

|

0.55

|

12.4

|

10.8

|

5/8

|

0.68

|

15.3

|

13.3

|

3/4

|

0.97

|

21.8

|

19.0

|

7/8

|

1.32

|

29.5

|

25.7

|

1

|

1.73

|

38.3

|

33.3

|

1 1/8

|

2.19

|

48.2

|

41.9

|

1 1/4

|

2.70

|

59.2

|

51.5

|

1 3/8

|

3.27

|

71.3

|

62.0

|

1 1/2

|

3.89

|

84.4

|

73.4

|

1 5/8

|

4.57

|

98.4

|

85.6

|

1 3/4

|

5.30

|

114

|

98.8

|

Safety

Working Loads and Factors of Safety

The

maximum load for which a wire rope is to be used should take

into account such associated factors as friction, bending load around

each sheave, acceleration and deceleration and if a long length of

rope is to be used for hoisting, the weight of the rope at its

maximum extension. The condition of the rope, whether new or old,

worn or corroded and type of attachments should be considered.

Factors of safety for standing rope usually range from 3 to 4; for

operating rope from 5 to 12. Where there is the element of hazard to

life and property, higher values are used.

Installing

Wire Rope

The main

precaution to be taken in removing and installing wire rope is

to avoid kinking which greatly lessens its strength and service life.

Thus, it is preferable when removing wire rope from the

reel to have the reel with its axis horizontal position and if

possible, mounted so that it will revolve and the wire rope

taken off straight. If the rope is in the coil, it should be unwound

with the coil in vertical position as by rolling the coil along the

ground. Where a drum is to be used, the rope should be run directly

into it from the reel, taking care to see that it is not bent around

the drum in a direction opposite to that on the reel, thus causing it

to be subject to reverse bending. On flat or smooth faced drums it is

important that the rope be started from the proper end of the drum. A

right lay rope that is being over wound on the drum, that is, it

passes over the top of the drum as it is wound on, should be started

from the right flange of the drum and left lay rope from the left

flange.

Lubrication

of Wire Rope

Although

wire rope is thoroughly lubricated during manufacture to

protect it against corrosion and to reduce friction and wear, this

lubrication should be supplemented from time to time. Types of

lubricant varies as the kind of ropes and operating conditions.

Maintenance

of Wire Rope

Heavy

abrasion, overloading and bending around sheaves or drums which are

too small in diameter are the practical reasons for the rapid

deterioration of the wire rope. Wire rope in use should

be inspected periodically for evidence of wear and damage by

corrosion. Such inspection should take place at progressively shorter

intervals over the useful life of the rope as wear tends to

accelerate with use. If there is any hazard involved in the use of

the rope, it may be prudent to estimate the remaining strength and

service life.